fire suppression system

Introducing to fire suppression system

Building a new structure and want to ensure that your vital machinery and resources are effectively secured from the destruction of a fire? Or maybe you’re in an old house with original fire safety devices and want to secure and save your current server room in case of a fire using our fire suppression system

Whatever your case, whether you are looking for the best fire prevention device for your company or hospital, a better understanding of what these systems are and what types are available will help you make the best decision for your specific needs.

Continue reading for a fast description of what constitutes a fire suppression device, a brief history of their creation, and an overview of the different forms that are now available for even the most vulnerable environments and equipment.

What is a Fire Suppression System?

In short, a fire suppression system is, to some extent, just what it sounds like – a system used to suppress and/or extinguish a fire inside a structure.

It is important to note that fire suppression systems are not the same as fire sprinkler systems. Fire sprinklers often use a large volume of water to extinguish and/or monitor a fire. Water damage to the contents of the room/building is normal as a result, but lives and the structure are saved.

However, other than water, other types of suppressing agents are used in fire suppression systems. CO2, chemical, and inert gases are examples of suppressing agents. These agents, as mentioned in depth below, have specific properties that make them perfect for protecting sensitive equipment and contents inside a building while also suppressing a fire.

A suppression system is designed to interfere before a fire has a chance to develop and spread, thereby mitigating potential damage. This also indicates that these devices activate at a much earlier stage in the production of the fire than fire sprinklers do.

"KABSON" AUTOMATIC FIRE TUBING SYSTEM

The automatic self-seeking fire tubing device extinguishes fires where they begin. Planned for use within enclosures and in inaccessible areas. There are no complicated electronics. Protected against failure. The highest price-to-performance ratio.

THE DIFFERENCE IN FIRE TUBE

- It functions as a multi-sensor and multi-extinguishing jet.

- Generated from a high-tech polymer.

- Long-term tolerance and flexibility are mixed.

- Temperature sensitivity, it ruptures as a nozzle form opening while bursting at the hottest place.

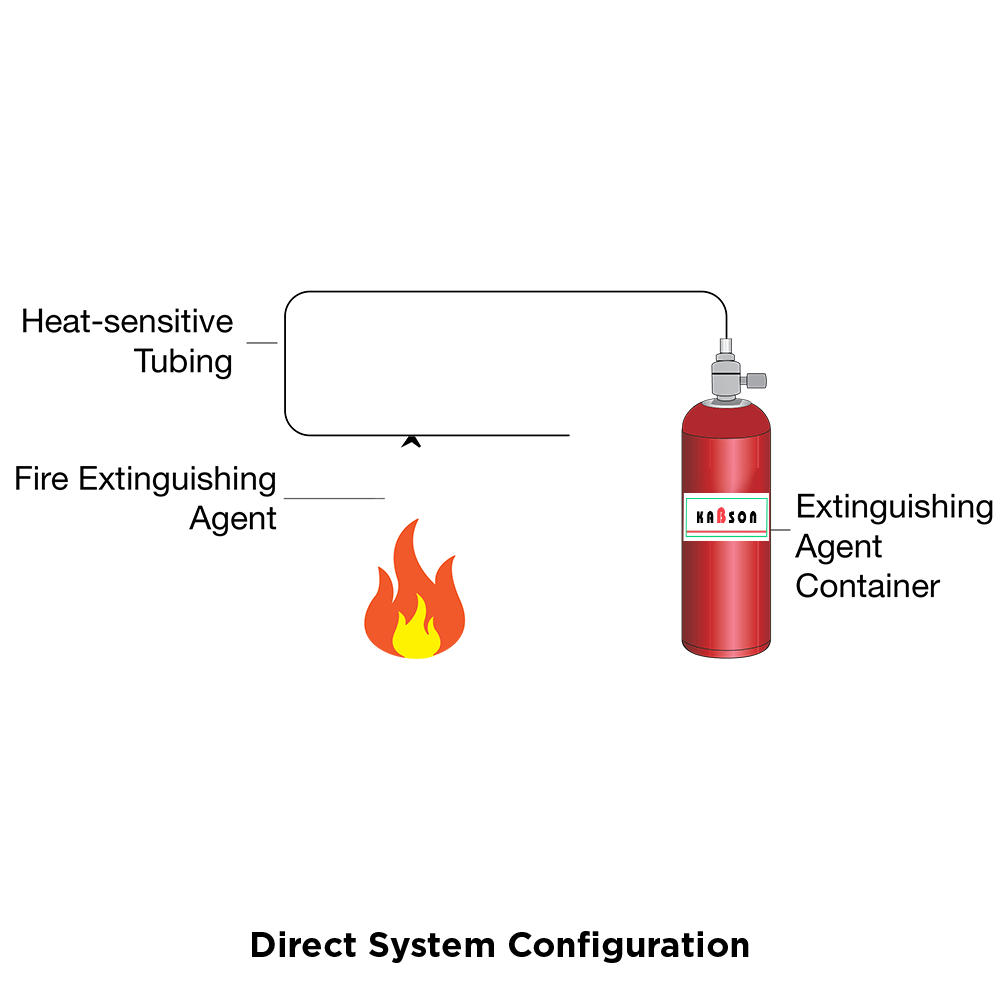

THE DIRECT SYSTEM

The “Kabson” fire fighter Direct Fast Suppression System is suitable for situations where fires can start in small spaces. The “Kabson” fire fighter Design Cell creates the Direct System, which is then implemented by “Kabson” fire fighter professional installers after an evaluation of the site.

Functioning

A specially designed release valve connects the multi-layered heat-sensitive modified polyamide tube to an extinguishing agent container. When a fire occurs, it induces a rapid rise in temperature. As the temperature exceeds 150° – 180° C, the heat-sensitive tubing bursts at the point where it comes into contact with the flame, forming a miniature nozzle. The agent then exits the container and passes through the miniature nozzle, flooding the enclosed localised region or micro-environment and extinguishing the blaze instantly.

Advantages

The benefits are obvious. A small fire that starts between endless rows of machines in a server can not be detected until it is far too late. This machine, on the other hand, can operate intricately and unobtrusively through servers, generators, and electrical mains boxes, and it is activated instantly and automatically. This removes the need for human interaction while also providing a fast and thorough solution.

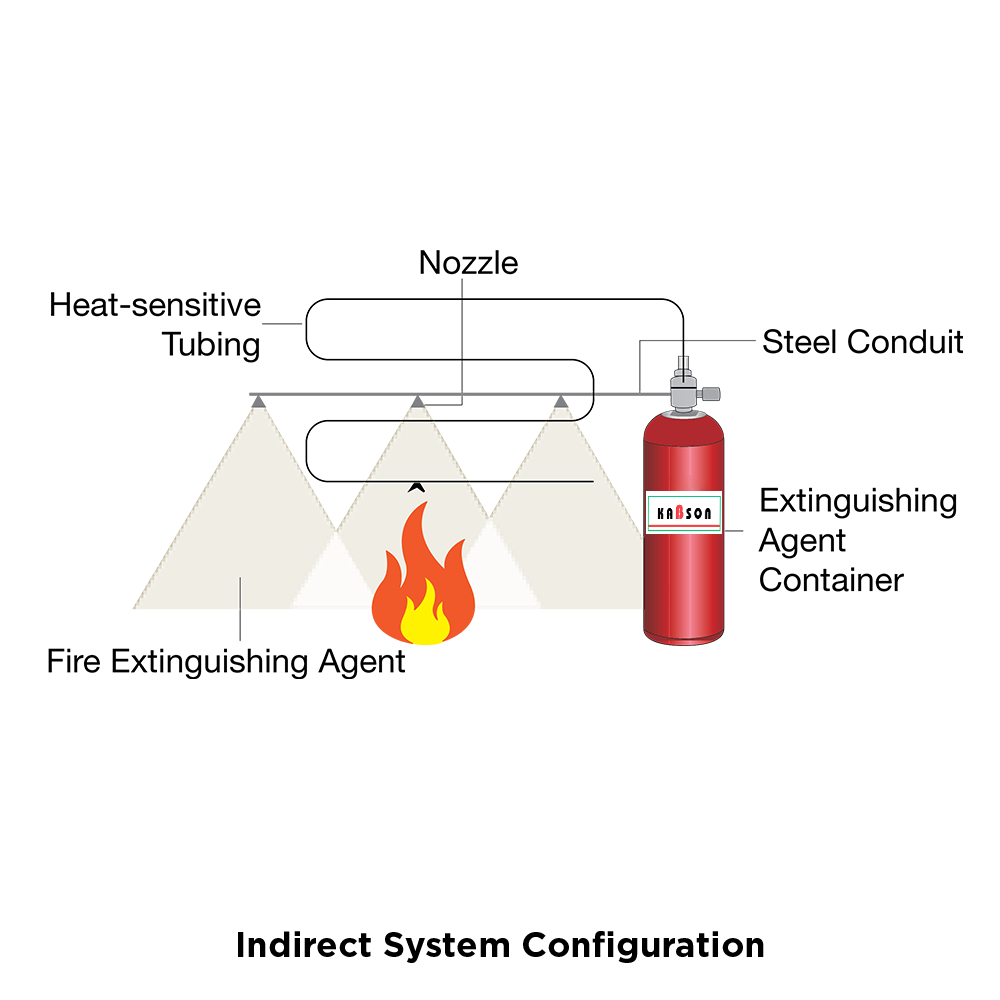

THE INDIRECT SYSTEM

The “Kabson” fire fighter Indirect Low-Pressure Suppression System is suitable for locations where there is a possibility of multiple points of fire ignition in a single or double compartment piece of equipment. A voltage surge, for example, can short-circuit components in multiple locations and cause them to catch fire in a large server rack, a UPS box, a CNC computer, a BUS engine, or an earth mover engine.

Functioning

When a fire breaks out in any area, the pneumatic tube senses it; when the pressure in the tube decreases, the in-direct pressure differential valves automatically activate. When the valve is opened, the extinguishing agent is forced out of the main cylinder through the metal pipework and sprayed via strategically positioned nozzles, resulting in complete flooding of the enclosed volume and total extinguishment.

Advantages

The flooding of the entire enclosure guarantees full extinguishment as well as the prevention of re-ignition. The main benefit of the indirect system is total flooding, and the pneumatic system is designed to be entirely independent of any physical, electrical, or electronic activation.

What Kinds of Fire Suppression Agents Are There?

Several fire extinguishing and suppressing agents are now used in a wide variety of fire suppression devices.

A sterile agent is discharged as a gas and leaves no residue, necessitating no cleanup (hence the word “clean”).

These gases are safe to use in human environments. They are preferred in places where sensitive equipment or resources are stored, such as server rooms, telecommunications rooms, maritime applications, vital military operations, rooms with medical equipment, libraries, and any other enclosures that may be considered high-value properties.

A large amount of CO2 gas is used in CO2 systems to suffocate a burn. It is highly dangerous to humans, so its use is generally very limited and limited to spaces with a high concentration of human inhabitants.

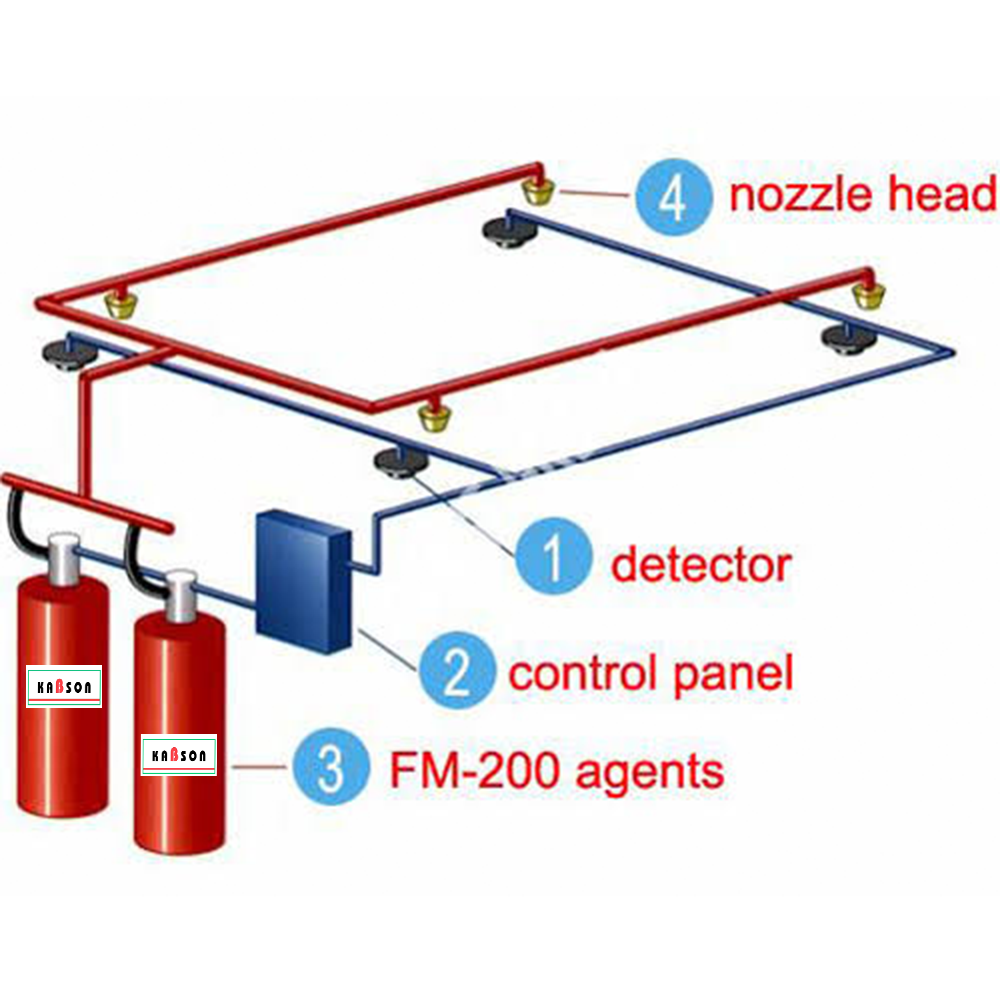

TOTAL

FLODDING SYSTEM

The flooding of the entire enclosure guarantees full extinguishment as well as the prevention of re-ignition.

The main benefit of the indirect system is total flooding, and the pneumatic system is designed to be entirely independent of any physical, electrical, or electronic activation.

Water does, in effect, extinguish the fire, but it also destroys valuable properties that might have been rescued from the fire but were destroyed as a result of the water.

The Total Flooding system employs specially formulated suppression agents to meet the fire safety needs of these areas while causing no harm to the assets.

We have a dedicated team that designs and commissions complete flood systems using clean agents such as HFC227ea (FM200), NOVEC1230, CO2, and inert gases that are safe to use and do not affect the environment or human life. Please contact us for more information on the customized solution.

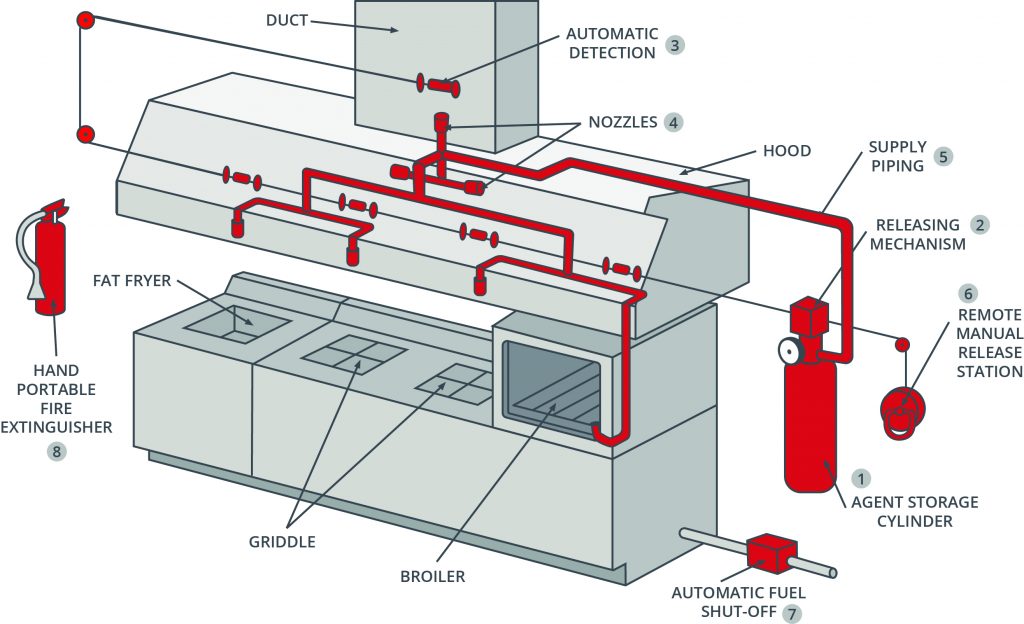

Kitchen Suppression System

Kitchen suppression is a wet chemical extinguishing device that works automatically to protect equipment, people, and property. Fires in industrial kitchens are common, and these suppression systems help to prevent them.

Industrial kitchens are a common source of fires, and they can be the most dangerous risk in a building, according to “Kabson” fire fighter. They’re also a vital part of your business that you can’t afford to do without, since they house critical equipment that’s costly to replace. To better protect your industrial kitchen from flames, we suggest kitchen suppression systems. Our technicians work with you to design a device that meets your needs, ensuring that your equipment is safe and your kitchen is back up and running as soon as possible in the event of a fire. This saves you time and money while also ensuring the safety of your employees, clients, and properties.

We are the leading fire suppression company that specializes in kitchens. All of our technicians are well qualified in all aspects of servicing and design, and they are available to re-engage your company after activation 24 hours a day, seven days a week. All maintenance is performed according to the manufacturer’s instructions.

Only genuine licensed parts are supplied and assembled by us. You can rest assured that your kitchen is safe from fire with “Kabson” fire fighter

Benefits

Extinguishers and fire blankets are not as secure or reliable as a kitchen suppression device. It does not require the presence of an operative and can be used to put out fires that have spread to kitchen canopies and extract ducts. It also helps the kitchen to be cleaned up right away, enabling regular operations to restart as soon as possible.

This means less harm to your property and a lower risk of injuries to your workers, as well as a lower financial effect on your business.

We are ecstatic to concede our association with

"ASR FIRE CHECK" for fire suppression system

We have strategic allowances with “ASR FIRE CHECK” on technology transmit

Fire Hydrant System

A fire hydrant system is a piece of protection or emergency equipment that is mounted in buildings and consists of a variety of components that, when placed together, provide a supply of water to help fight fires. A fire hydrant is an active fire safety mechanism and a source of water provided in most metropolitan, suburban, and rural areas with municipal water service to enable firefighters to use the municipal water supply to help extinguish a fire. It improves the firefighting capability of a location where it is deployed effectively. These hydrated systems are used in a variety of applications besides firefighting, such as water transport, irrigation, and so on.

Such systems use a well-designed water delivery system, which includes a water tank and fire pumps, to combat fires. It also has a distributed piping system that connects pipes, nozzles, and hydrants in the house. The primary goal of a fire hydrant system is to provide the best available water supply to each corner of the building. It assists in the safety of the building by literally putting out a fire in an emergency.

Advantages

- A fire hydrant system is an efficient way to put out a fire in a building that could cause extensive damage.

- Because of its massive piping system, the system can combat a fire from a long distance.

- It has more penetration capabilities than other fire safety systems since it protects every point of the house. Simply put, its key advantage is its high accessibility.

- Hydrant valves are strategically located in the house, ensuring that no area is left unprotected.

Fire Sprinkler System

Sprinklers are lightweight, self-contained devices that are triggered by the heat of a fire. Hot gases rise to the ceiling as a fire begins. If a sprinkler is present, a glass bulb or solder connection heats up to the point that it splits at a certain temperature (usually 68°C), releasing a cap and enabling water to flow onto a diffuser.

The diffuser divides the water flow into small, precisely regulated droplets that penetrate the fire plume and cool the burning material below its ignition point, effectively putting out the fire. Only the sprinklers that are immediately above the fire are turned on.

Sprinklers are attached to pipework that is normally filled with water that comes from the water mains or a storage tank through a pump. When a sprinkler is activated, the water movement in the pipework activates a flow switch, which activates a warning device. The water flow is minimal, normally less than 1/100th of what the Fire and Rescue Service uses.

Dependable and trustworthy

Sprinklers are not activated by mistake and are only activated in the event of a real fire. They’re also highly dependable, with just one sprinkler out of every 16,000,000 exhibiting some kind of manufacturing error.

Transformer Suppression System Divulge Valve Technology

What is the purpose of transformer protection?

To be more precise and transparent, let us use an example. Even if an oil-cooled transformer is made of metal, the oil is likely to catch fire if a certain temperature is exceeded, and the entire transformer will immediately catch fire and burn from all sides. We use a Water Spray System to prevent this type of burn.

A detector is nothing more than a temperature sensing element, and there may be several metal rings of detectors here. This detector ring is positioned near the most probable sots where a temperature exceeds or a fire is about to occur. In addition, the entire transformer is engulfed by several sprays at different stages. A sprinkler without the temperature-sensing bulb is known as a spray.

When a fire happens, the detector ring detects it and sends a signal to the deluge valve, which triggers all of the sprinklers surrounding the transformer to trigger simultaneously. To cool it down, the whole transformer is flushed with water.

In conclusion:

In the event of a fire, the Quartzoid Bulb Detector (QBD) will burst at rated temperature due to heat, allowing water in the detection pipe to drain and the top chamber pressure of the Deluge valve to drop, allowing the Deluge valve to completely open.

Water can flow through the piping to all water spray nozzles installed on the piping around the transformer as soon as the Deluge valve opens. The water should be sprayed in a hollow conical spray pattern to cover the entire region of the transformer, allowing the fire to cool due to emulsification and extinguish due to the nozzle’s coverage pattern cutting off oxygen.

Water Mist Suppression system

Water mist is a fire-fighting medium that is both flexible and reliable. The smaller droplet size of Water Mist sets it apart from conventional water-based systems. A droplet of water expands 1,600 times as it vaporizes. Since heat absorption is proportional to surface area rather than volume, smaller droplets have more surface area and thus absorb heat more quickly.

Water Mist is the only commodity on the market that can offer water as a fine atomized mist. This mist soon turns to steam, suffocating the fire and preventing further oxygen from reaching it. At the same time, evaporation reduces the cooling effect of combustion gases and prevents radiant heat transfer. Water Mist incorporates the fire-fighting capabilities of both traditional water-based deluge or sprinkler systems and gaseous fire suppression systems in this way.

“Kabson” fire fighter offers both a low-pressure and a high-pressure variant of Water Mist applications, using the special properties of Water Mist to provide your facility with the best solution in the event of a burn.

Water Mist systems – low pressure solution

Water mist systems are similar to conventional sprinkler and Water Spray Deluge Systems in terms of ease of use and reliability; the only difference is the smaller droplet size. As a result, heat absorption is increased and water damage is reduced. Sealed Nozzles for sprinkler-equivalent systems and Open Nozzles for complete flood systems are available on water mist systems.

Water Mist systems – high pressure solution

The Water Mist systems – high pressure solution is a complete flood device that protects Class B flammable liquid hazards in machinery spaces, including insulated and non-insulated combustion turbine enclosures, generator enclosures, and flammable liquid storage.

Foam Mist Suppression system

Foam fire control systems put out fires by cooling them down and separating the fuel from the oxygen. The systems are used to “cool the fire and coat the fuel that the fire absorbs to avoid contact with oxygen and minimise any combustion ability,” in more technical terms. The extinguishing agent blankets or smothers the fuel’s surface to accomplish this.

The water content of the foam will cool the fuel, and the region of foam covering the fuel will prevent flammable vapours from igniting. To suffocate and cool a fire, high expansion foams fully fill the volume of a building from floor to ceiling

Foam suppression systems are similar to wet sprinkler systems in that they store water and send it through a network of pipes before discharging it through several sprinklers or nozzles. The inclusion of foaming agents separates foam systems from other conventional wet sprinkler systems. The foaming agent is kept separate from the water in a tank, and the two are mixed together in the piping system before being discharged. A nozzle or sprinkler is located at the end of the piping. When water and foaming agent combine, a foam-water mixture forms, which is then discharged onto the fire.

Foam fire suppression devices are usually used in larger environments of flammable or combustible liquids. Some of the most popular applications include:

- Storage facilities for aerosols, paint, and alcohols

- Hangars for planes

- Sites where jet engines are tested

- Applications in the marine environment

- Facilities for the preparation and distribution of flammable liquids

Selecting the Best Fire Suppression System

Clearly, there are several choices to consider when selecting the appropriate fire suppression device for your situation. The best one for you is determined by the applications you need as well as the facility, tenants, and materials you need to secure.

We will clarify the intricacies of fire suppression systems and assist you in choosing the right one for your needs.